Completion of the main installation of four thousand tons hydraulic press-Huan Guan Group

1098Completion of the main installation of four thousand tons hydraulic press-Huan Guan Group

View Full VersionPlease enter the keywords you want to search Site-wide search Product News

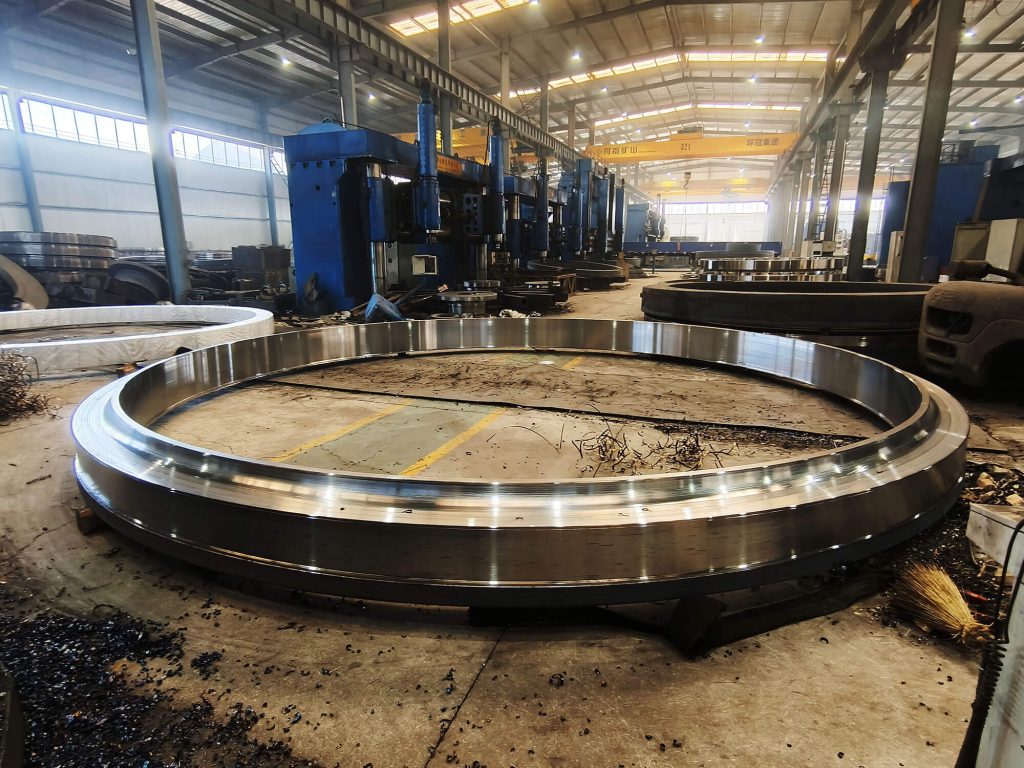

Our company is specializing in the production of: wind power tower flange, wind power brake disk flange, wind power spindle and autoclave flange, glass kettle flange, pressure vessel flange, elbow fittings, shaft forgings, ring forgings, cylinder forgings, wheel forgings, pipe plate blind plate, rotary kiln big gear ring big gear, rotary furnace big gear ring big gear, big gear ring big gear of the ball mill, rotary kiln wheel with rollers, ball mill wheels with rollers. Tel:Ms. Wang:18035446366

Completion of the main installation of four thousand tons hydraulic press-Huan Guan Group

View Full VersionForging and forging have their own advantages and disadvantages, decide which process is better quality depends on the specific production situation and requirements. First, the basic concept of forging and forging Forging refers to the use of a variety of forging machinery to deform and process metal materials manufacturing process. Among them, forging is the use of high-pressure forging machine will be heated metal materials pressed into the desired shape, forging is to hammer the metal...

View Full Version10,000-ton press installation completed and put into production

View Full VersionAre all forgings tempered after forging?

View Full Version

Hello!sign in